Global marine refrigeration specialists with Greek excellence and Nigerian presence

24/7 Expert Technical Support for Marine Refrigeration & Air Conditioning Systems

At Refrigerator Base Enterprise, we provide comprehensive technical support services for all marine refrigeration and air conditioning systems. Our team of certified engineers and technicians is available 24/7 to ensure your vessel operations remain uninterrupted.

Complete technical support for all marine refrigerator systems including fish holds, cargo refrigeration, and provision cooling systems.

Expert support for marine air conditioning systems including cabin cooling, engine room ventilation, and electronics cooling.

Specialized support for compressed air drying systems essential for marine instrumentation and pneumatic controls.

Comprehensive support for all refrigeration machinery onboard vessels, including specialized fishing and cargo ship systems.

Receive your technical support request via phone, email, or WhatsApp

Our experts analyze the issue and determine the best course of action

Provide remote guidance or dispatch technicians as needed

Ensure resolution and provide detailed service documentation

Our team of certified marine refrigeration engineers is available 24/7 to resolve your technical issues.

New & Reconditioned Compressors from World-Leading Manufacturers

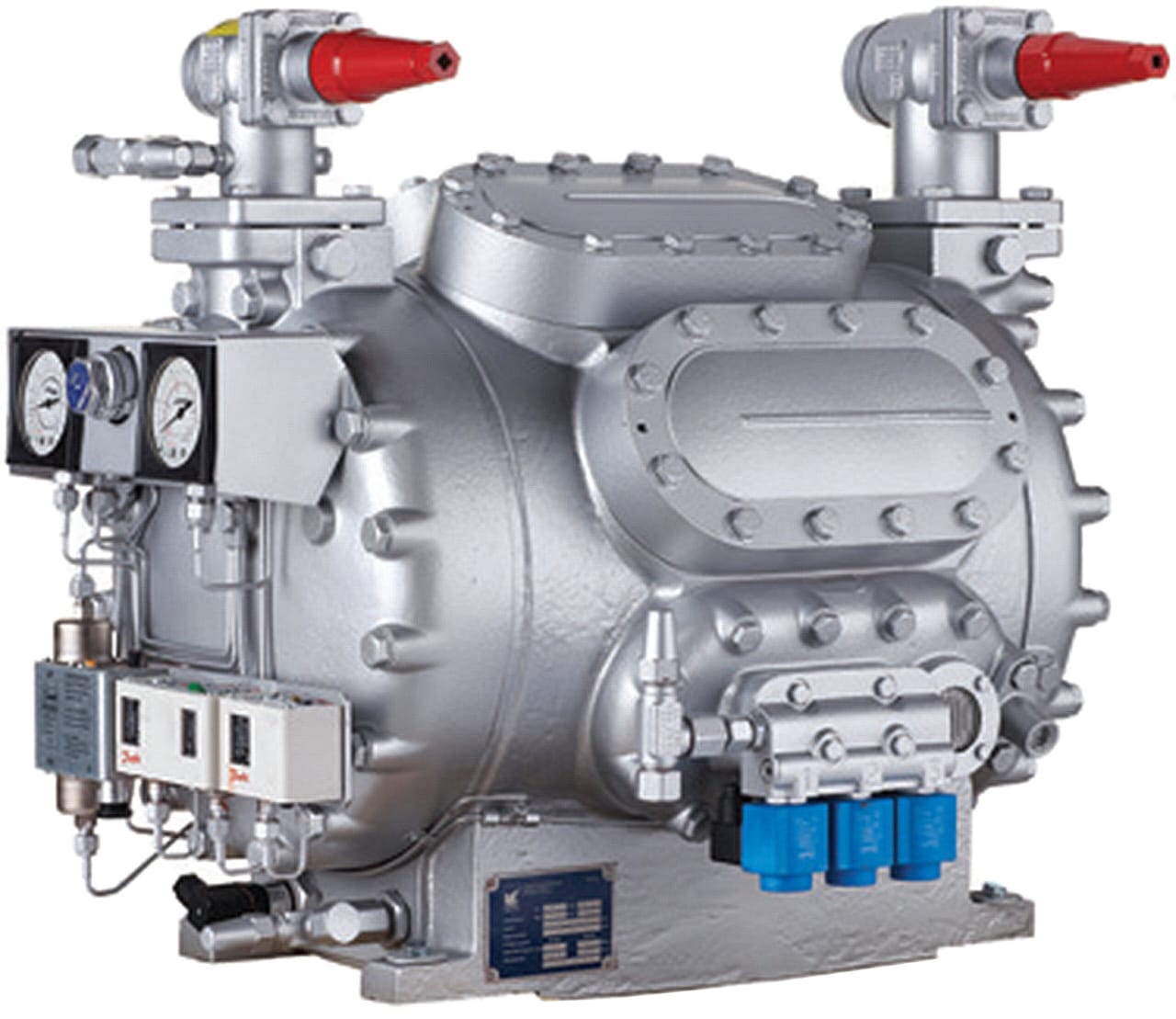

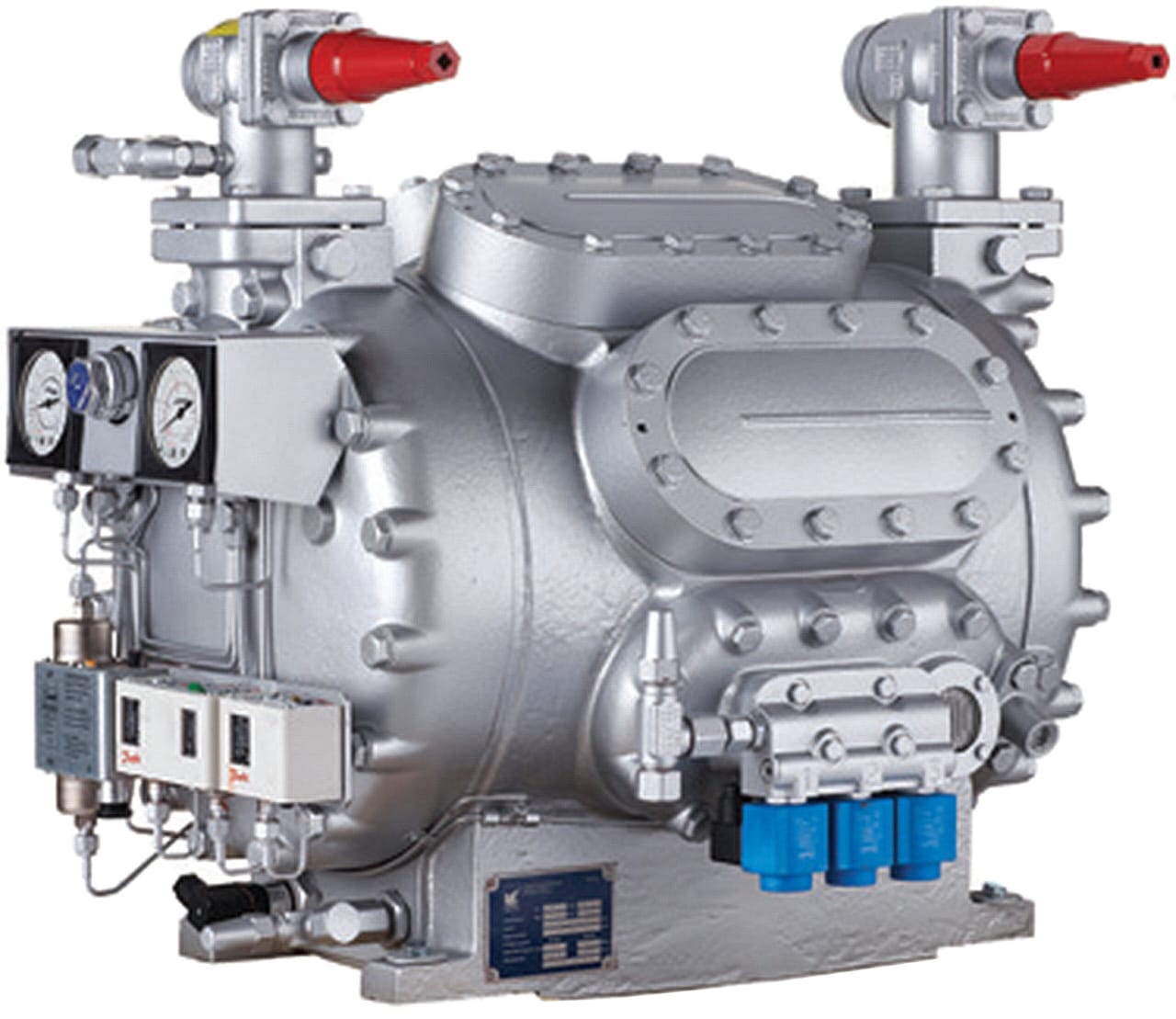

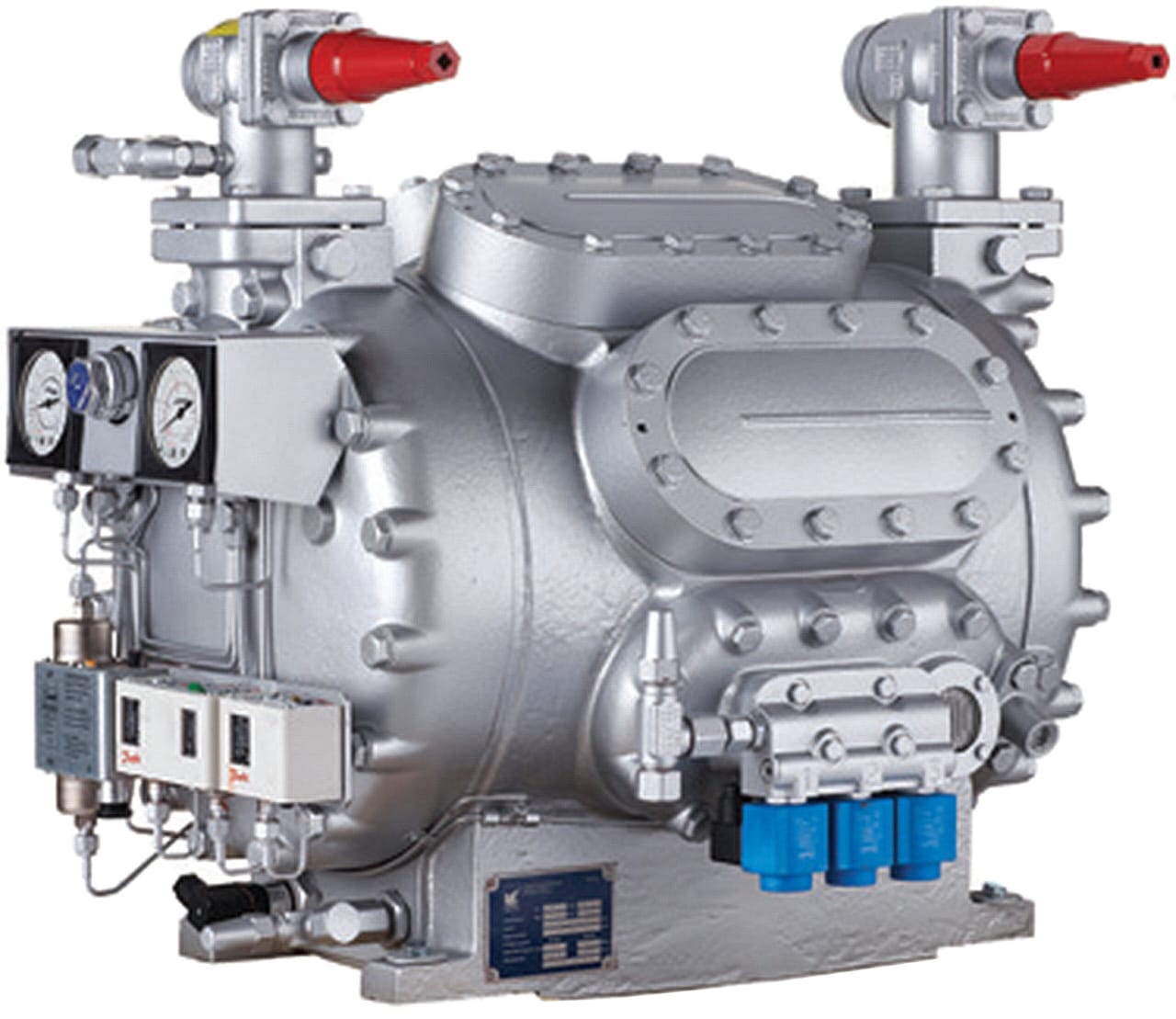

World-renowned marine refrigeration compressors for heavy-duty applications

SABROE is a global leader in marine refrigeration compressors, known for their reliability, efficiency, and durability in harsh marine environments. Our SABROE compressors are designed for heavy-duty applications including fish holds, cargo refrigeration, and provision cooling systems.

We supply both new SABROE compressors and professionally reconditioned units that undergo complete overhauling, testing, and come with full performance guarantees.

| Model Series | Capacity Range | Refrigerant | Power (kW) | Type | Application |

|---|---|---|---|---|---|

| SAB 150 | 50-150 TR | R134a, R404A | 40-120 | Screw | Fish Hold |

| SAB 300 | 100-300 TR | R407C, R22 | 75-220 | Screw | Cargo Refrigeration |

| SAB 500 | 200-500 TR | Ammonia | 150-370 | Reciprocating | Industrial Marine |

| SAB Marine | 20-100 TR | R134a | 15-75 | Reciprocating | Provision Cooling |

Get competitive pricing for SABROE compressors and spare parts. Our team will provide detailed specifications and delivery information.

Premium marine air conditioning and refrigeration compressors

CARRIER compressor content would follow the same structure as SABROE above.

Replace with actual CARRIER compressor information, specifications, and images.

Energy-efficient screw and reciprocating compressors

BITZER compressor content would follow the same structure as SABROE above.

Replace with actual BITZER compressor information, specifications, and images.

Reliable scroll and semi-hermetic compressors

COPELAND compressor content would follow the same structure as SABROE above.

Replace with actual COPELAND compressor information, specifications, and images.

Heavy-duty centrifugal and screw compressors

YORK compressor content would follow the same structure as SABROE above.

Replace with actual YORK compressor information, specifications, and images.

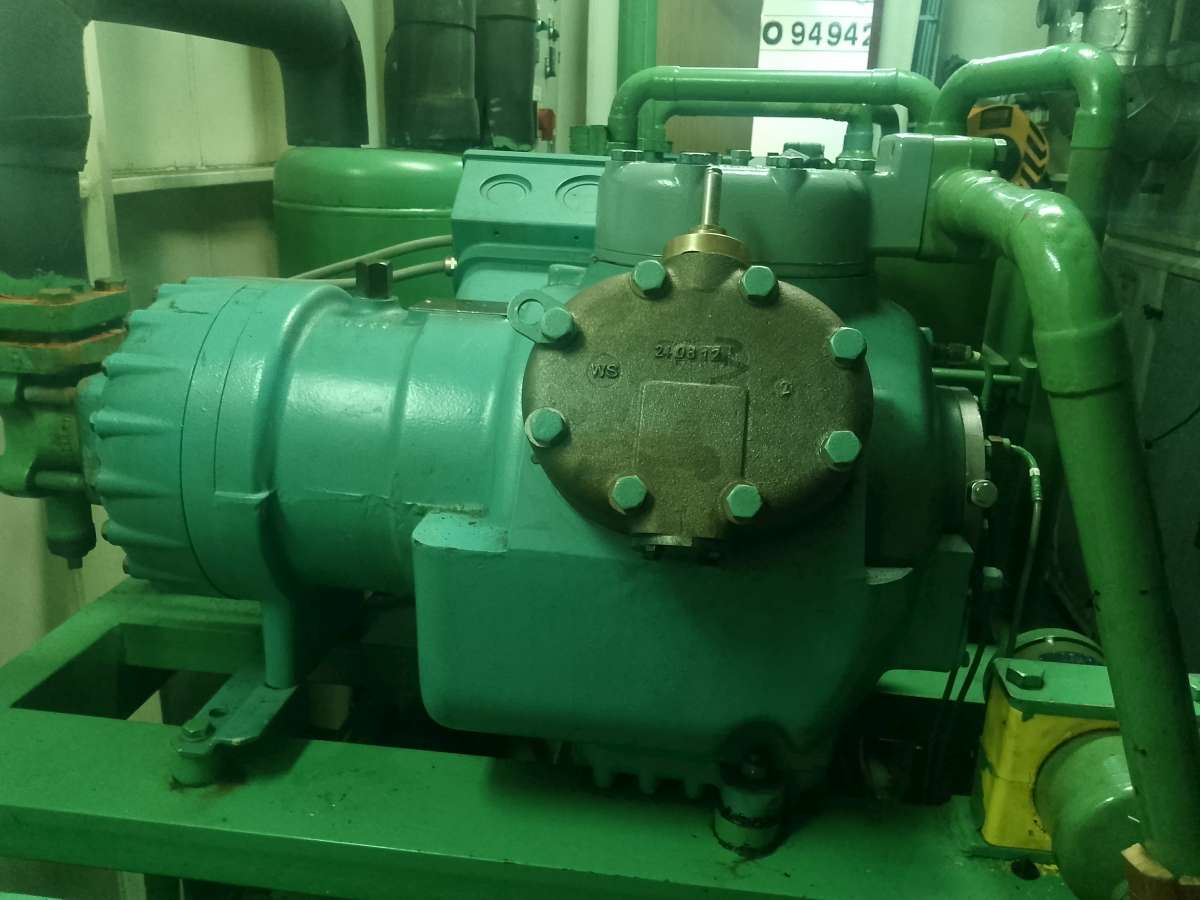

Complete Compressor Overhaul, Repair & Testing Facility

Our fully equipped workshop in Lagos, Nigeria specializes in the complete overhaul, repair, and testing of all types of marine refrigeration compressors. From SABROE to CARRIER, BITZER, COPELAND, and YORK compressors, we handle every aspect of compressor restoration with precision engineering.

Click to view our workshop facility and repair process

Comprehensive repair and overhaul services following international marine standards

Systematic disassembly of compressors using specialized tools and equipment, ensuring no damage to components.

Comprehensive component analysis using precision measuring instruments and NDT methods to identify wear and defects.

In-house machining workshop with CNC and conventional machines for component reconditioning and fabrication.

Complete electric motor rewinding services with Class H insulation for marine environmental conditions.

Comprehensive performance testing under simulated operating conditions to ensure reliability and efficiency.

Precision assembly using calibrated torque wrenches and following manufacturer specifications.

Our systematic approach ensures quality and reliability at every stage

Document condition, initial testing, and damage assessment

Systematic disassembly and component organization

Ultrasonic cleaning and detailed component analysis

Machining, welding, and component restoration

Electric motor rewinding with marine-grade insulation

Precision assembly with new seals and gaskets

Performance, leak, and vibration testing

Final inspection and certification

Proper packaging for marine transport

Every repaired compressor comes with a comprehensive performance guarantee and full documentation.

Contact our workshop team for a free assessment and quote. We handle emergency repairs and scheduled overhauls for all major compressor brands.

Standard repair: 5-7 days

6-12 months warranty